China RPET&RPP Manufacturing Wholesale

Guangxi Wuzhou Guolong Environmental Protection and Recycling Resources Technology Co., Ltd, established in March 2012, is located in the Wuzhou Circular Economy Industrial Park.We have developed a comprehensive RPET and RPP recycling system, operating a complete closed-loop value chain from collection to recycled pellets production, including washing, sheet manufacturing and thermoforming processes.

Our Environmental Impact

By choosing our sustainable packaging solutions, you're contributing to these positive environmental outcomes:

Our Product Categories

Cherry Containers

The sweet, delicate nature of cherries demands packaging that provides both protection and presentation. At GuoLong, we've engineered our premium RPET RPP cherry containers to showcase these ruby-colored treasures while maintaining optimal freshness from orchard to consumer.

Blueberries Containers

Blueberries require specialized packaging to preserve their bloom, prevent crushing, and maintain freshness. RPET RPP blueberry containers are engineered specifically to protect these delicate fruits while showcasing their natural beauty through crystal-clear recycled materials.

Meat Trays

In the premium meat sector, packaging must do more than simply contain—it must preserve quality, extend shelf life, and enhance visual appeal. GuoLong's RPET RPP meat trays are engineered specifically for protein products, combining superior performance with environmental responsibility.

Egg Cartons

Eggs demand specialized protection that balances visibility, shock absorption, and environmental responsibility. RPET RPP egg cartons deliver exceptional performance while meeting the growing consumer demand for sustainable packaging solutions.

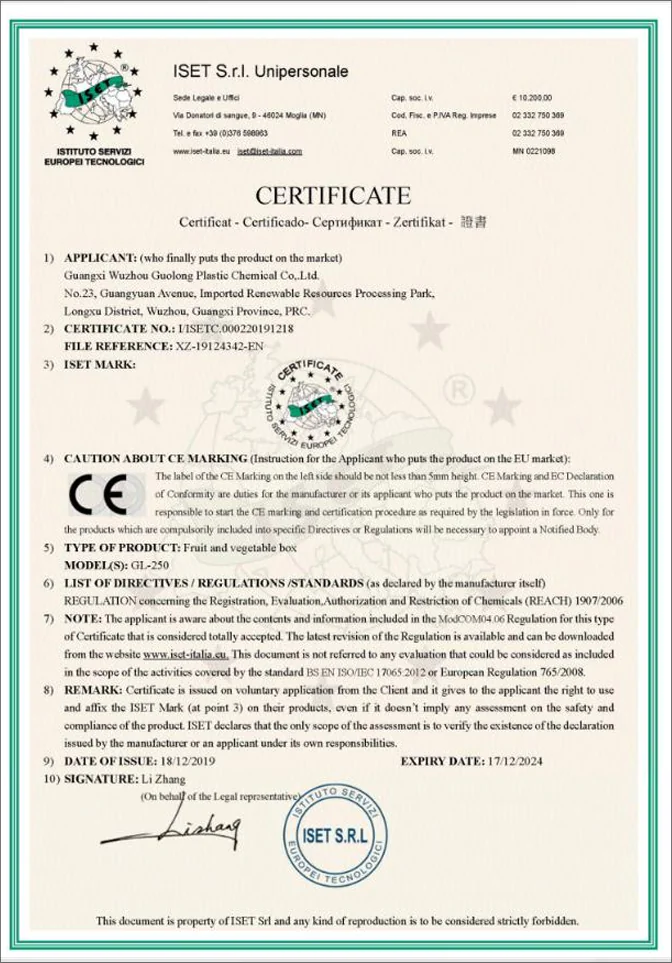

Vegetable Carton

Fresh vegetables require packaging that balances protection, respiration, and visual appeal while minimizing environmental impact. RPET RPP vegetable cartons deliver superior shelf life extension while meeting growing consumer and regulatory demands for sustainable packaging.

Drink Cups

Today's beverage industry demands packaging that delivers exceptional performance, visual appeal, and environmental responsibility. RPET RPP beverage cups offer crystal clarity and superior functionality while meeting growing sustainability requirements across global markets.

Company Timeline

Tracing our journey of innovation and growth in sustainable recycling solutions

2012: INCORPORATION

Guangxi Wuzhou GuoLong Recycling Resources Development Co., Ltd established in Longxu District Circular Economy Park with 316.8 mu of factory and office land.

2013: GLOBAL RESEARCH

Chairman Guo led research across 26 countries, studying 50+ cases on recycled plastics industry prospects, processes and equipment.

2014: PlANT CONSTRUCTION

Factory construction completed with PET, HDPE, PP washing workshops, granulation workshop, and thermoforming facilities built to Industry 4.0 standards.

2015: IMPORTED EQUIPMENT

Imported leading international recycling equipment adapted to Chinese recycled plastic characteristics, developing GuoLong's core proprietary technology.

2016: EQUIPMENT ADJUSTMENT

SOREMA PET washing line equipment delivered, with international technical team conducting installation and debugging.

2018: PET CLEANING LINE

SOREMA PET washing line officially launched, becoming Asia's largest single-line capacity with ¥160 million investment.

2020: PET SHEET PARTICLES

SML & EREMA three-layer ABA structure PET sheet production line and food-grade R-PET particle production line launched with ¥65 million investment.

2021-2025: HDPE PP PARTICLES

AVIAN HDPE/PP washing line, EREMA food-grade R-HDPE/R-PP pelletizing lines, and KIEFEL thermoforming and KTR6.1 high-speed cup production lines launched with ¥80 million total investment.

Our Value Propositions

Discover why our sustainable packaging solutions stand out in the industry

GuoLong Proprietary Core Technology

GuoLong Recycling has partnered with global industry leaders to adopt premium international equipment. After 9+ years of R&D, we've adapted technologies from multiple global suppliers to China's specific recycling needs, resulting in production lines with our proprietary technology that meets international standards.

Larger Capacity, Better Price

With our advanced manufacturing capabilities, LingGao delivers an impressive annual production capacity of up to 230,000 tons of RPP and RPET materials per year. This substantial output allows us to meet the demands of even the largest global clients while maintaining consistent quality across all orders.

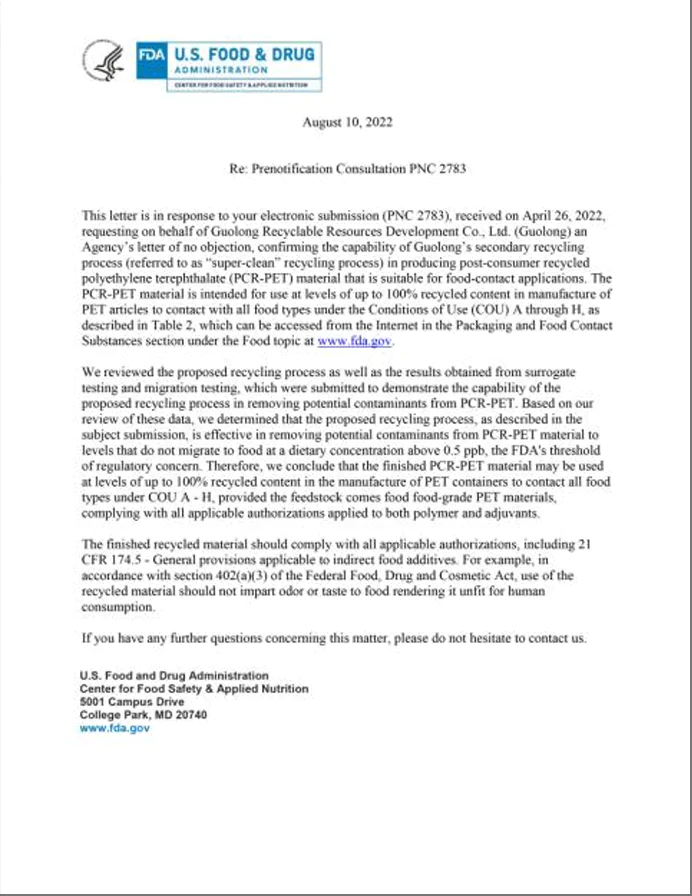

Certified Products, Safety Guaranteed.

Guo Long adheres to comprehensive international certifications including FDA, GRS, SCS, BRC, CE, and ISCC PLUS standards. This robust compliance framework ensures our recycled PET products meet the highest global requirements for food safety and sustainability.

Our Advanced Manufacturing Equipment

Explore our state-of-the-art factory equipment that enables us to deliver precision products with exceptional quality and efficiency.

SOREMA Complete Plastic Bottle Washing Line

SOREMA Complete Plastic Bottle Washing Line delivers premium recycling for PET/PP containers with integrated sorting, grinding, washing, and drying. Processing 3000kg/hour at 98% purity, our energy-efficient system reduces water usage by 40% while effectively removing all contaminants. Built with stainless steel components and intuitive controls, this turnkey solution consistently produces high-quality rPET flakes meeting the strictest industry standards.

TOMRA (Germany) Optical Sorting Equipment

TOMRA's German-engineered optical sorters represent recycling technology excellence. Using multi-spectral cameras, NIR sensors and AI algorithms, these systems deliver 99.9% sorting purity while processing 8+ tons hourly. They precisely differentiate between polymer types, colors and contaminants, featuring self-calibration, touchscreen operation and remote monitoring. TOMRA equipment maximizes uptime, reduces operational costs, and sets the global standard for sustainable plastic recovery operations.

EREMA (Austria) Sheet Production Line

EREMA's Austrian-engineered sheet lines transform PET flakes into premium food-grade sheets with exceptional clarity. Featuring patented vacuum degassing, 38-micron filtration and intelligent controls maintaining ±0.02mm thickness tolerance. Processing 500-2000 kg/hour with 30% better energy efficiency, these systems produce FDA/EFSA-compliant sheets for thermoforming. Integrated automation with remote diagnostics minimizes downtime, making EREMA the global leader for sustainable packaging manufacturers.

SML (Lenzing) Sheet Production Line from Austria

SML's Austrian-engineered sheet production line delivers exceptional RPET/RPP sheet precision with Lenzing technology. Offering thickness variations under ±0.01mm, it features multi-layer co-extrusion, patented measurement systems and intelligent tension control for superior clarity and mechanical properties. Processing 600-2500kg/hour with rapid material changeover, the system combines advanced PLC automation with proprietary SMILE monitoring software. The result: sheets with outstanding flatness and optical qualities perfect for high-performance food packaging applications.

German KIEFEL Thermoforming Machine

KIEFEL's German-engineered thermoforming machine delivers precision packaging excellence with servo-driven mechanics achieving 45 strokes per minute. Its innovative plug-assist system and patented pressure-forming technology ensure optimal material distribution and exceptional detail in RPET sheets. Featuring the proprietary KMD control system with intuitive touchscreen interface, it enables quick mold changes and precise temperature control. Globally trusted by leading manufacturers to produce containers with superior clarity, dimensional stability and consistent wall thickness.

American AVIAN Whole Bottle Plastic Washing Line

AVIAN's American-engineered Whole Bottle Plastic Washing Line delivers cutting-edge PET recycling efficiency. This system features multi-stage processing with pre-washing, high-temperature caustic bath and friction cleaning stations, achieving 3,000kg/hour throughput with 99.97% contaminant removal. Its energy-efficient design reduces water consumption by 40% through advanced recirculation technology. Fully automated controls with remote monitoring capabilities ensure consistent food-grade rPET flake quality while minimizing labor requirements - ideal for high-volume recycling operations.

Global Reach & Production Excellence

Trusted by businesses across the globe with industry-leading production capacity

Export Countries

Our sustainable packaging solutions are exported to over 30 countries across 5 continents, meeting international quality and safety standards.

European Countries

Asian Markets

North American Regions

South American Countries

African Nations

Total Countries

Production Capacity

Our state-of-the-art facilities operate 24/7 to deliver high-quality sustainable packaging solutions at scale, ensuring timely fulfillment of orders of any size.

ISO 9001

FDA Approved

BRC Certified

ISCC PLUS

Eco-Friendly

Request Your Custom Packaging Solution

Our team of experts is ready to help you create the perfect sustainable packaging for your products. Get a personalized quote tailored to your specific needs.